Our commitment to quality

For someone who values life, advocacy, and family. It's always a challenge to find ways to protect oneself against a potential attack.

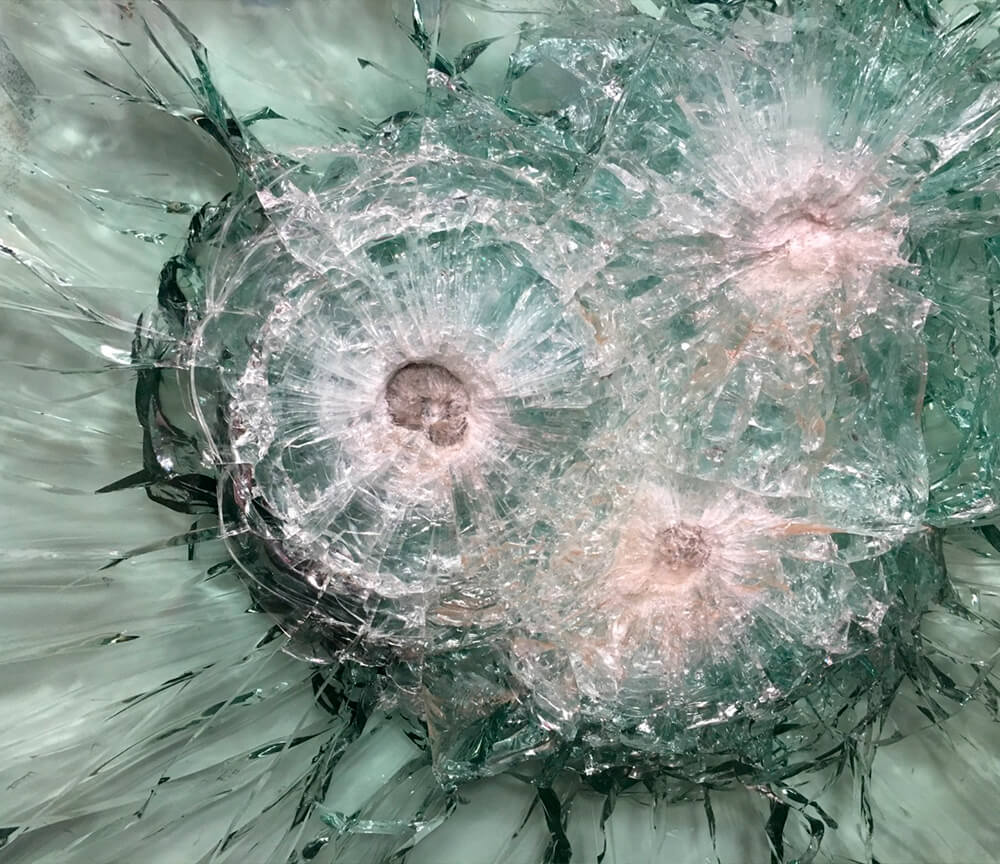

In the Philippines, the threat environment has become increasingly complex and strategically focused. Attacks can happen while driving a vehicle or from the comfort of their home. The recent and frequent threat consists of projectiles of a long weapon, which at high velocity and whose potential effect lies in their kinetic energy. The category of long firearm includes rifle that is operable with two hands and have a 7.62 or 5.56 calibre.

RGQ understood this principle, and thus, we see to it that the armoring process of each vehicle on the production follows strict guidelines and procedures in welding and ballistic installation.

We are passionate and committed to providing high-quality vehicle armoring protection to SAVE LIVES. We ONLY use independently tested and internationally certified ballistic materials in our armoring process to guarantee our customer a safe and secure armored vehicle.